Modern manufacturing and industries are racing already towards what we call 4th Industrial Revolution, or more technically stated as Industry 4.0. The necessity of a digital transformation of the manufacturing processes is considered indisputable, but it was also pushed drastically to an accelerating rhythm due to the late challenges brought on by the COVID-19 pandemic that affected society and business globally, proving that digital tools were crucial to go forward.

This development ‘’vehicle’’ towards Industry 4.0 moves so fast, that many SMEs or individual professionals struggle to keep up with the digital transformation tools and the innovative technologies that are emerging. The technology and the state-of-the-art tools already exist, but a bigger effort is needed to be integrated to the modern floorplan.

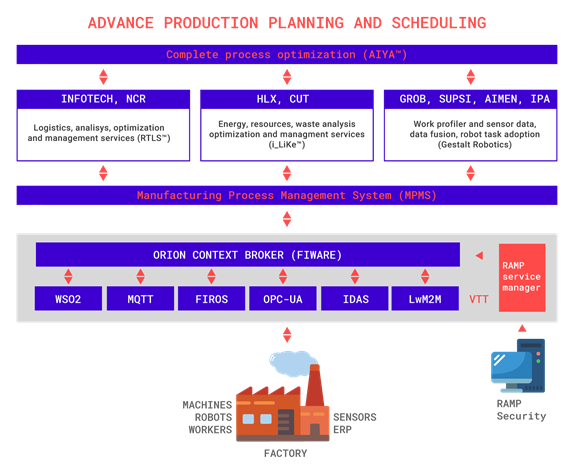

Therefore, Better Factory as an Innovation Action under the Innovation for Manufacturing SMEs (I4MS) initiative is developing an open and standardized Advance Production Planning and Scheduling (APPS) with the mentoring of technical personnel, complemented with a more integrated approach, with the involvement of artists and business mentors.

APPS is a highly advanced system with all latest commercial tools for the optimization of waste, energy and resources, something that in the modern tech terminology is referred to as Lean-Agile Production[1], where technologies such as 3D-printing and in general Additive Manufacturing are introduced to create novel materials more efficiently (less energy), with a lower cost, better properties and less waste.

On the other hand, APPS offers innovation in logistics and material flow handling with the introduction of Automated Guided Vehicles (AGVs) and mobile robots interconnected in a smart way in the factory floorplan. Moreover, workers, engineers and managers can interact with the machinery according to their involvement in the process through Cyber-Physical Systems (CPS) for cognitive Human-Robot-Interaction (HRI) resulting into faster, simplified and more efficient outcomes.

APPS will be promoted mainly through two perspectives: First, the involvement of artists in the development of APPS will increase its acceptance in many manufacturing sectors by developing, modifying and individualizing product concepts providing creative ideas for personalized products and second, through structured online trainings SMEs will be able to understand and learn how to implement APPS in their production.

In conclusion, Better Factory will deploy APPS on its free and open Internet of Things (IoT) platform, RAMP, to transform traditional manufacturing SMEs into fully connected cyber–physical systems. All leading to Automated Logistics and Lean-Agile Innovative production on, transforming the floorplan to an efficient, low cost, low waste, state-of-the-art unity complying with the modern requirements of the industry.

[1] https://www.tutor2u.net/business/reference/introduction-to-lean-production#:~:text=Lean%20production%20is%20an%20approach,and%20responsive%20to%20market%20needs.