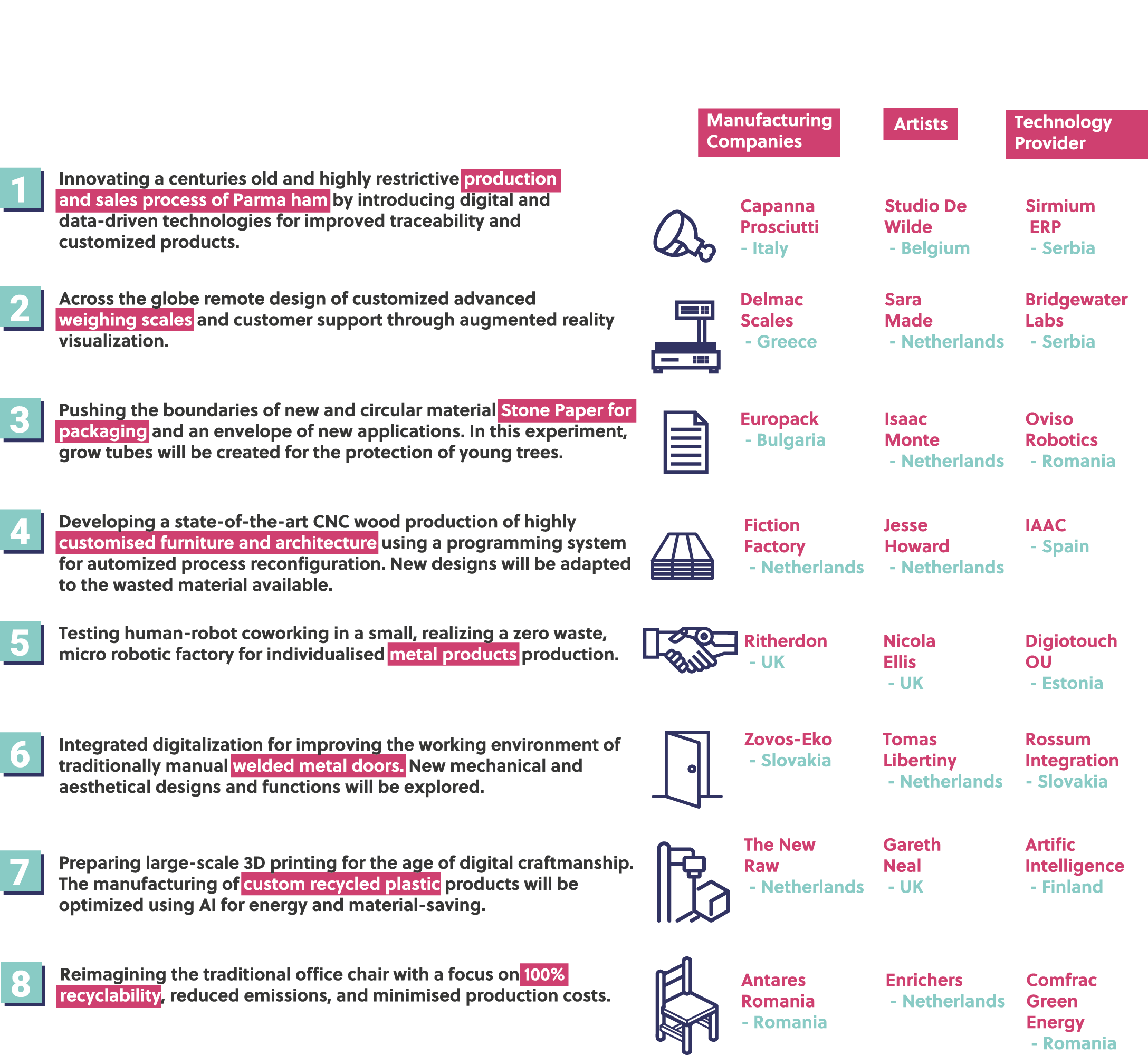

What are the Better Factory KTEs?

The Knowledge Transfer Experiments (KTEs) aim at transforming the Manufacturing SMEs and Mid-Caps into optimum Lean-Agile factories with manufacturing and delivery of new and/or personalized products and services as their business strategy.

In each KTE, an Artist is supporting the SME in the development of new and personalized products and services, while a Technology Supplier is managing the installation of the APPS and additional services developed by them.

Meet the KTE teams

Supervised manufacturing of real-time traceability in ham production

Introduction of a digital and data-driven approach for full traceable and optimal production of traditional premium Parma ham customized products.

Digital Solutions for Better Scales Factory

Implementation of agile/lean manufacturing principles for optimized pre-sales, production, and after-sales of customized advanced weighting equipment.

Exploring Product Customisation and Robotic Fabrication in a Small Factory

Testing the limits of human-robot co-working within a small, sheet-metalworking smart factory.

Better CNC Factory

Deployment of Lean-Agile production system for efficient CNC Wood Manufacturing of highly customed furniture or architecture products.

Modular Cobot for production of Stone Paper Innovative Products

From handmade cellulose-based paper solutions to efficient automated production of stone paper products.

Optimization of Digital Craftmanship in 3D Printing

AI and craftmanship combination for optimized and efficient 3D printing of customized recycled plastic products.

Welded Metal Door Design, Fabrication, and Innovation

Introduction of creative solutions for the redesign and optimization of the existing metal door production.

The 100% Recyclable and Circular Office Chair

Reimagining the traditional office chair with a focus on 100% recyclability, reduced emissions, and minimised production costs.

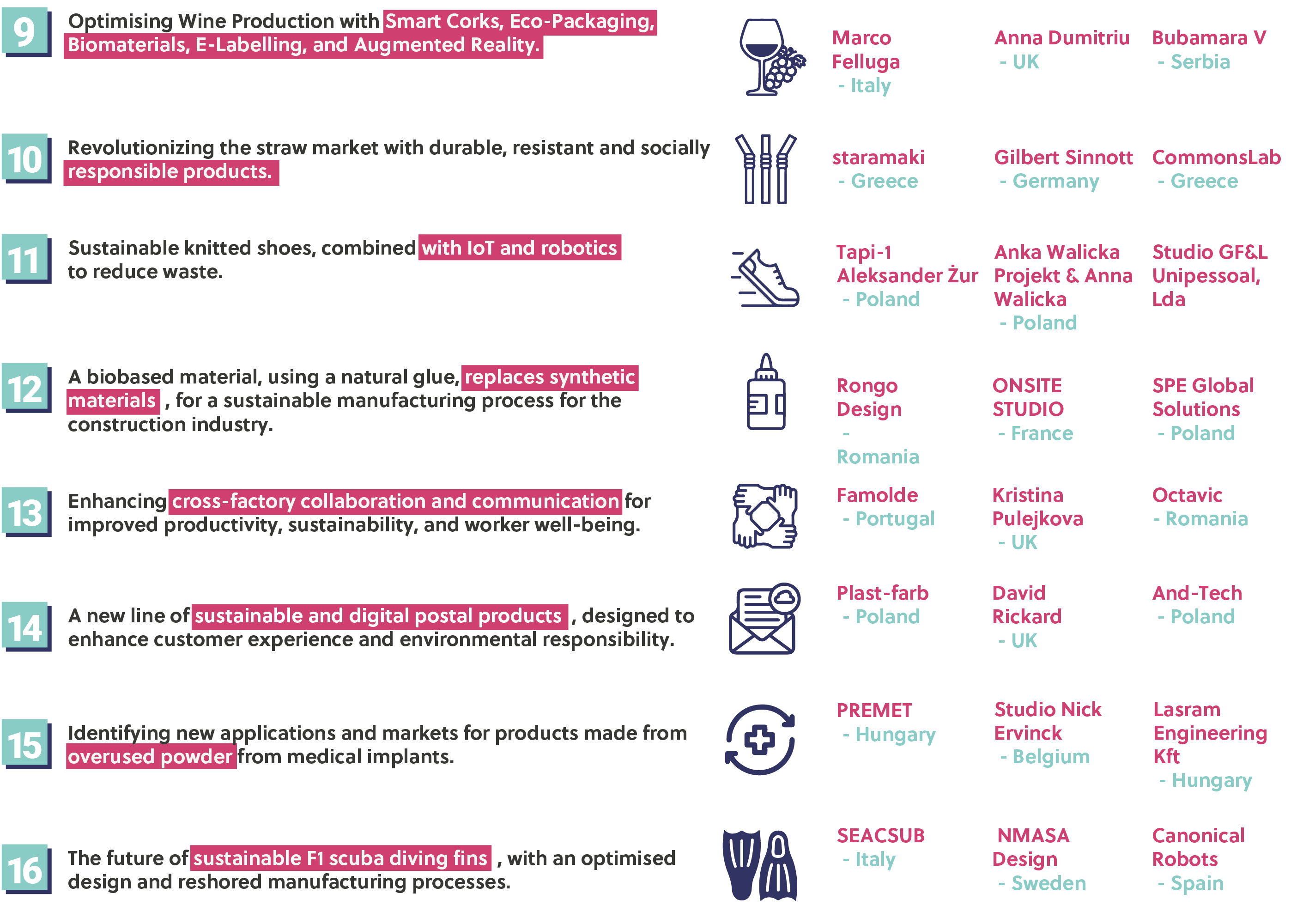

Bio-Inspired Glue for Sustainably Manufactured Products

A biobased material, using a natural glue, replaces synthetic materials, for a sustainable manufacturing process for the construction industry.

Sustainable Wine Production with AR and Robotics

Optimising Wine Production with Smart Corks, Eco-Packaging, Biomaterials, E-Labelling, and Augmented Reality.

Sustainable straws, greener future

Revolutionizing the straw market with

durable, resistant and socially responsible products.

Factory floor collaboration at your fingertips

Enhancing cross-factory collaboration and communication for improved productivity, sustainability, and worker well-being.

Digitalised and eco-friendly envelopes

A new line of sustainable and digital postal products, designed to enhance customer experience and environmental responsibility.

Transforming metal waste into opportunity

Identifying new applications and markets for products made from overused powder from medical implants.

Dive deeper

with less impact

The future of sustainable F1 scuba diving fins, with an optimised design and reshored manufacturing processes.

Have fun building our origami flyer!