Better Factory participated at the European Robotics Forum event that took place online the past 13-15 of April 2021. The workshop Accelerating productivity with robotics was a joint initiative with the contribution of L4MS and Robotics and Automation Marketplace (RAMP).

Analyzing experience from L4MS project and building on the perspective of the Better Factory project, the panel started with RAMP benefits by Ali Muhammad, Better Factory project coordinator. RAMP marketplace works as the front‐end of RAMP IoT Infrastructure and provides Data Analytics and Benchmarking tools and a number of advance digital solutions for agile production.

It is a one‐stop‐shop for Manufacturing SMEs for all the technologies and services such as access to experts and infrastructure from regional DIHs, access to finance, advanced training to reskill workers, legal and business advice, etc. RAMP Marketplace has been developed in L4MS and DIH² projects and will continue with new EU projects SHOP4CF, Better Factory and BOWI.

To continue, Success Stories from SMEs involved in the L4MS funded experiments, presented by Angelos Streklas, using the Logistic Automation Library (OPIL). And, funding opportunities for manufacturing SMEs through the Better Factory project by Natalia Cardona.

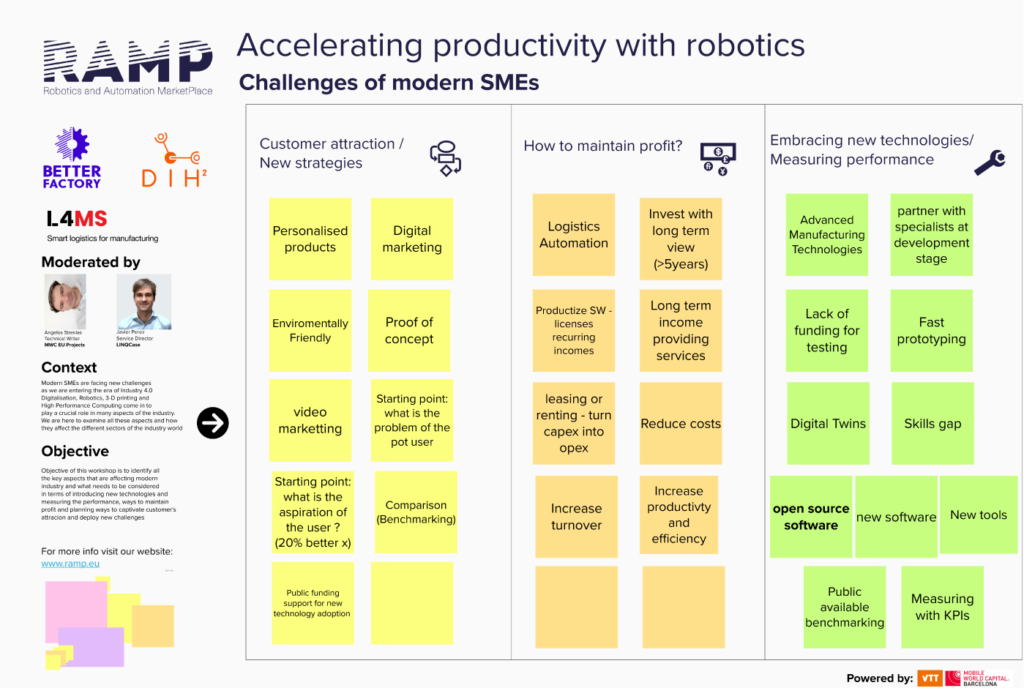

The session was concluded with a collaborative brainstorm on Challenges of Modern SMEs, where participants could discuss and suggest ideas under a live session with Javier Perez, Service Director at LINQcase, and Angelos Streklas, Technical writer at Mobile World Capital Barcelona. The main objective of this workshop was to identify all the key aspects that are affecting the modern industry and what needs to be considered in terms of captivating customer attraction, ways to maintain profit, and strategies to adopt new technologies and measuring performance.

So, in terms of customer attraction participants focused on the need for digital marketing tools, the presentation of a rigid proof of concept, and personalised products. Maintaining profit, leasing or renting methods, and reducing costs by introducing automation were the main contributions from the audience. As for embracing new technologies, most attendees mentioned Digital Twins, Advanced manufacturing Technologies, covering the skills gap and the use of open-source software.

The conversation was fruitful, and the conclusions will help manufacturing SMEs envision new solutions on the upcoming challenges and project partners to perceive an overview and feedback on their developed tools from different projects.