The Better Factory project, an EU-funded initiative aimed at boosting manufacturing SMEs’ global competitiveness through art and technology expertise, has been making significant strides in fostering innovation.

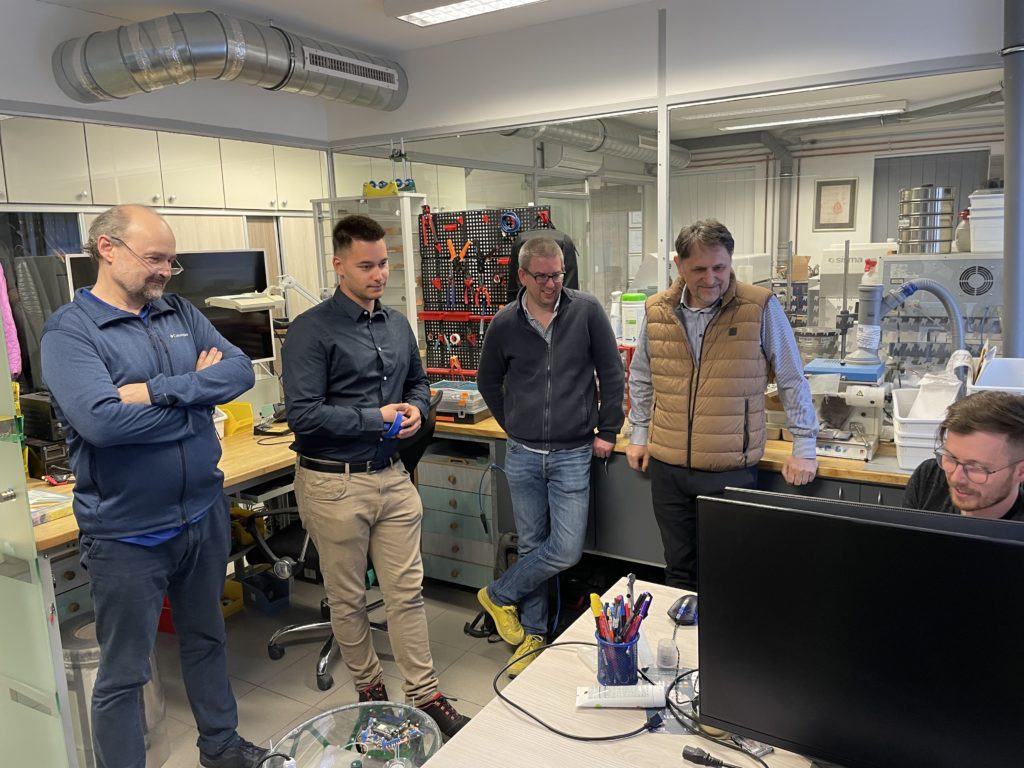

Over the past few weeks, Better Factory’s project partners and mentors have embarked on a series of visits to the new Knowledge Transfer Experiment (KTE) teams, providing an invaluable opportunity to meet the teams in person, witness their work up close, visit their factories, and strengthen relationships across the project. This article delves into the recent visits and highlights some of the exceptional teams that have become beneficiaries of the Better Factory project.

The Better Factory project in a nutshell

Before we dive into the visits, let’s briefly recap what the Better Factory project entails. Funded under the European Commission H2020 programme, this initiative is committed to empowering European manufacturers to enhance their competitiveness in the global market. By offering up to EUR 200,000 in equity-free funding, the project supports collaborative intra-factory experiments spanning a 16-month period. This endeavor aims to transform traditional factories into lean-agile production facilities capable of manufacturing both new and personalized products alongside existing ones.

During the initial round of the Better Factory project, eight teams from 12 European countries pioneered innovative processes that captivated the industry. From revolutionizing centuries-old Parma ham production to implementing zero waste metal production through human-robot coworking, these visionary teams pushed the boundaries of what was deemed possible. Another remarkable achievement was the development of a new circular material known as Stone Paper, designed to protect young trees. These success stories set the stage for the second round of the project and paved the way for new teams to join the Better Factory community.

Introducing the new beneficiaries

Following an intensive selection process, nine exceptional teams were chosen to participate in the second round of the Better Factory project.

Let’s take a closer look at these innovative teams and the manufacturing challenges they are tackling, as well as some of the pictures from the recent visits to their factories!

OCCE

The 100% Recyclable Office Chair

This team are working on a reimagining the traditional office chair with a focus on 100% recyclability, reduced emissions, and minimised production costs.

- Manufacturing company: Antares Romania

Romania - Artist: Enrichers

Netherlands - Technology Provider: Comfrac Green Energy

Romania

IOWA (Internet of Wine and Art)

Sustainable Wine Production with AR and Robotics

This team are working on optimising Wine Production with Smart Corks, Eco-Packaging, Biomaterials, E-Labelling, and Augmented Reality.

- Manufacturing company: Marco Felluga

Italy - Artist: Anna Dumitriu

United Kingdom - Technology Provider: Bubamara V

Serbia

STARIOT

Sustainable straws, greener future

This team are working on revolutionizing the straw market with durable, resistant and socially responsible products.

- Manufacturing company: staramaki

Greece - Artist: Gilbert Sinnott

Germany - Technology Provider: CommonsLab

Greece

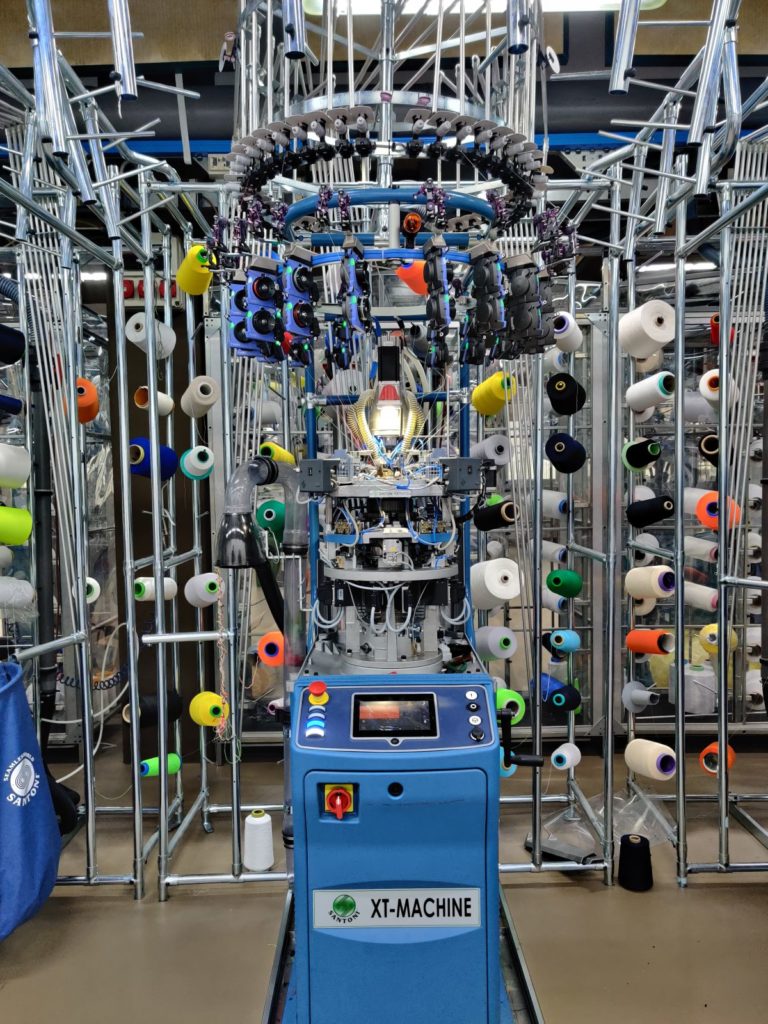

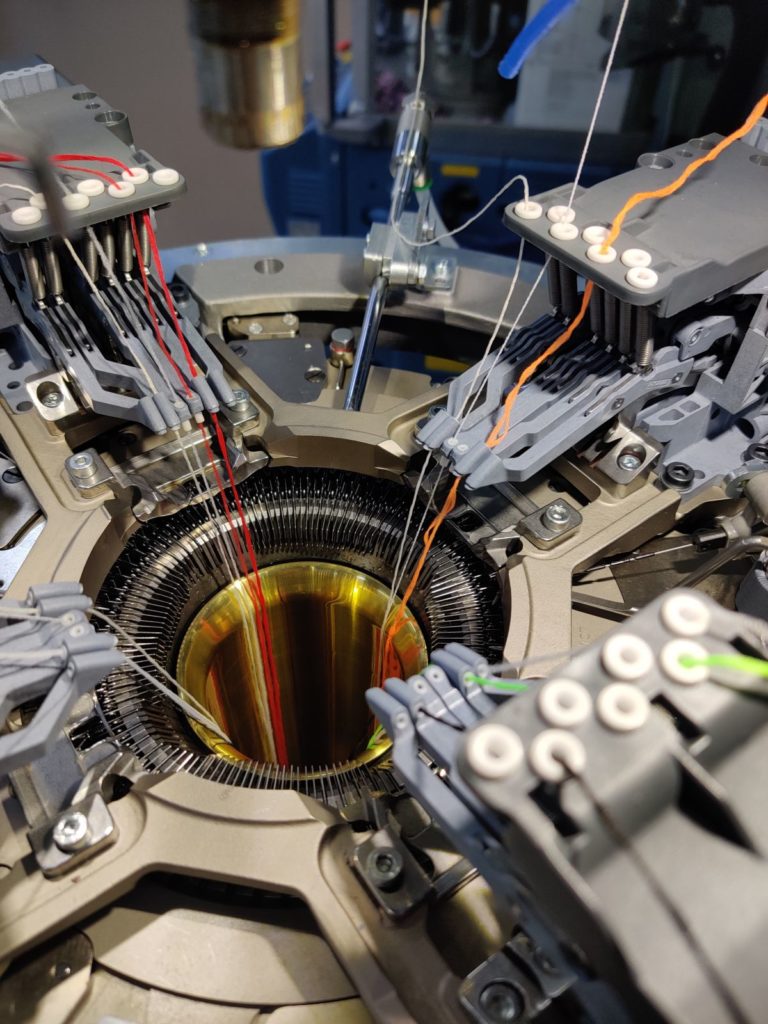

SHOES IN CIRCLE

Your footprint, reduced

This team are working on making sustainable knitted shoes, combined with IoT and robotics to reduce waste.

- Manufacturing company: Tapi-1 Aleksander Żur

Poland - Artist: Anka Walicka Projekt & Anna Walicka

Poland - Technology Provider: Studio GF&L Unipessoal, Lda

Portugal

MICOCRAFT

Bio-Inspired Glue for Sustainably Manufactured Products

This team are working on a biobased material, using a natural glue, replaces synthetic materials, for a sustainable manufacturing process for the construction industry.

- Manufacturing company: Rongo Design

Romania - Artist: ONSITE STUDIO

France - Technology Provider: SPE Global Solutions

Poland

SMARTVIEW

Factory floor collaboration at your fingertips

This team are working on enhancing cross-factory collaboration and communication for improved productivity, sustainability, and worker well-being.

- Manufacturing company: Famolde

Portugal - Artist: Kristina Pulejkova

United Kingdom - Technology Provider: Octavic

Romania

SMART ENVELOPE

Digitalised and eco-friendly envelopes

This team are working on a new line of sustainable and digital postal products, designed to enhance customer experience and environmental responsibility

- Manufacturing company: Plast-farb

Poland - Artist: David Rickard

United Kingdom - Technology Provider: And-Tech

Poland

3 DART DESIGN

Transforming metal waste into opportunity

This team are working on a identifying new applications and markets for products made from overused powder from medical implants.

- Manufacturing company: PREMET

Hungary - Artist: Studio Nick Ervinck

Belgium - Technology Provider: Lasram Engineering Kft.

Hungary

ReFINE

Dive deeper with less impact

This team are working on creating the future of sustainable F1 scuba diving fins, with an optimized design and reshored manufacturing processes.

- Manufacturing company: SEACSUB

Italy - Artist: NMASA Design

Sweden - Technology Provider: Canonical Robots

Spain

The recent visits by partners and mentors to the new beneficiaries of the Better Factory project have cemented the bonds between the teams and the wider project community. As these teams embark on their innovation journey, their work promises to shape the future of manufacturing and contribute to the global competitiveness of European SMEs. With ongoing support, collaboration, and engagement, the Better Factory project continues to pave the way for a more innovative and sustainable manufacturing landscape.

Follow the new KTE teams’ journey

If you’re intrigued by the cutting-edge innovations these teams are working on, there are various ways to stay connected. Follow Better Factory on Twitter and LinkedIn, sign up for our newsletter, and keep an eye out for upcoming European events announced on our blog. By engaging with the Better Factory project, you can witness the progress made by these visionary teams and contribute to the vibrant manufacturing innovation community!