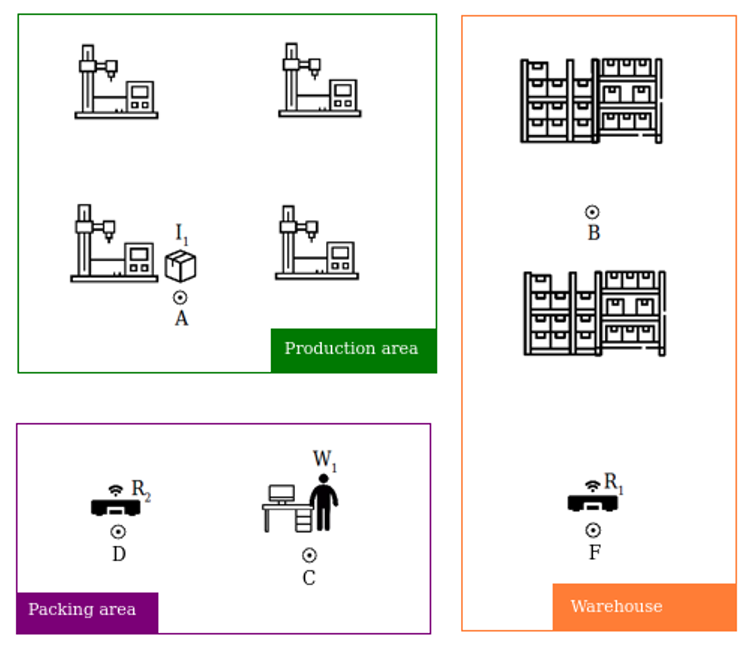

The solutions allows for scenario verification for factory process changes before implementation. Based on descriptions and targets from the user, the solution calculates if the desired target is feasible to achieve, and if so, how to do this.

The production manager collects the required information on the agents in the factory and feeds this to the software module. The module runs the analysis and delivers the scenario outcome in the form of a report.

It helps factories run scenarios before making investment decisions. Therefor it contributes to the knowledge to base decisions on.

A computer with an internet connection and a person to feed the required information to the program.

Improve decision making knowledge on process changes by xx%. *Pending after KTEs experimentation

Better CNC Factory

Business Process Optimization