FACTSHEET: Advanced Plant Model (APM)

Solution

How does it work?

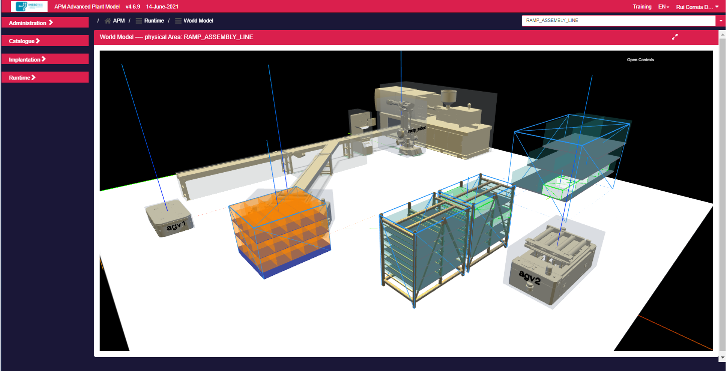

The solution is an easy to use Factory 3D Designer which can be shown in an internet browser with the functionality to interact with robots on the factory floor.

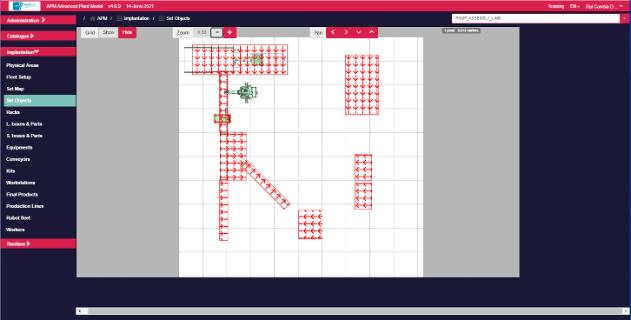

Each user should built their own geometric catalogue of objects and factory layout map, after which the map can be populated with the objects.

What problem does it solve?

What is needed to use it?

Most digital twin solutions are complicated and specific. This one is easy to create and start using on any device with an internet connection.

A computer with an internet connection

KPI's / Numbers

Who is using it?

Allows for xx % of factories to create a digital twin hassle free. *Pending after KTEs experimentation

FOLD, Better CNC Factory, ZOVOS-EKO, SMARTHam, DSBSF, MiniRoboFab

Images

Training Content

Advanced Plant Modelling and 3D Digital Twin

The Advanced Plant Model (APM) aims to provide a real-time digital representation of the ongoing state of a given shop floor including the representation of workers, industrial and mobile robots, work-stations, manufacturing lines, racks, boxes, palettes, kits and parts, consolidated by a production schedule generated by a Manufacturing Execution Sytem (MES).

The Digital Twin Designer is the element inside the APM system that provides the means to enable the User to build the digital representation of manufacturing areas.

🎥 Complementary video of the documentation

🎥 KTEs Webinar on Advanced Plant Model

- How to login into the APM

- Create Physical Area

- Create Physical Area (video)

- Implant objects on the physical area

- Create Physical Area with Map

- Create Physical Area with Map (video)

- Add a new rack to the Catalogue

- Add a new rack to the Catalogue with STEP

- Add new equipment to the catalogue

- Add a new workstation to the catalogue

- Add a new production line to the catalogue

- Digital Twin Designer User Manual

- Integration with the OPIL server – Part 1

- Integration with the OPIL server – Part 2